Electric Submersible Pumps

ESP systems for diverse applications and environments

Electric submersible pumps (ESPs) produce in dynamic well environments that challenge both well and pump-operating efficiency.

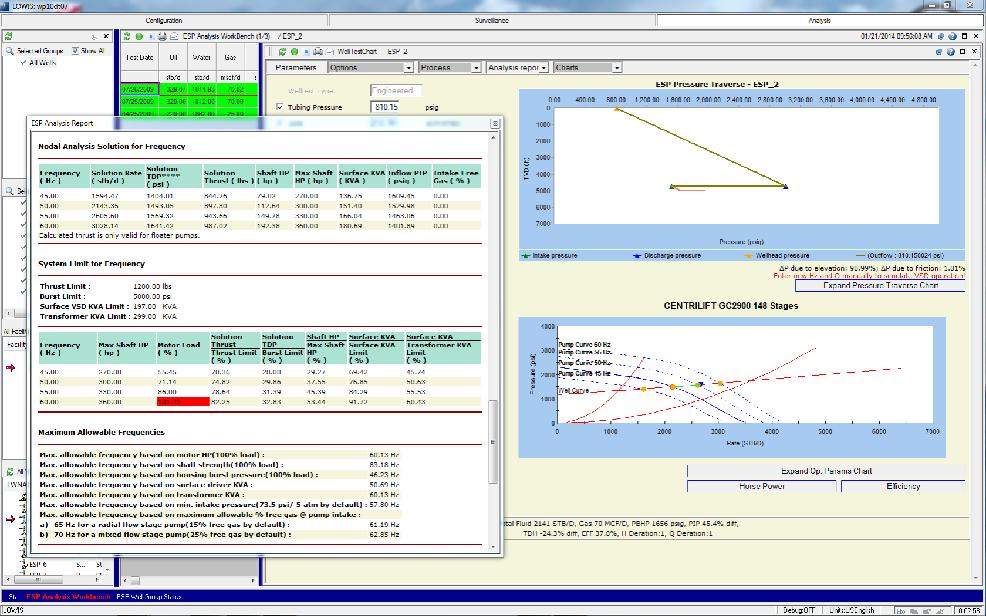

Optimizing the operation of an ESP system not only stabilizes production in a changing well environment, but also maximizes the life of the pump. To achieve optimal performance, it’s essential to monitor and analyze ESP well performance, including pump intake and discharge pressures, gas-to-oil ratio, and water cut.

Choosing the right gas-lift equipment helps ensure maximum reservoir productivity and operational efficiency. Whether you have a low-producing conventional well, high-producing shale well, or prolific deepwater well, Litewell gas-lift experts can help you get the most from your assets.

At Litewell, our comprehensive software systems and electronics optimize ESP operation and oil production. We can deliver longer ESP run life, better ESP system diagnostics, and valuable reservoir-pressure data.

Because ESP performance goes far beyond hardware, our experienced team offers well design, engineering, and installation followed by monitoring, analysis, fine tuning, and commissioning.

Our optimization systems and software are installed all over the world. We deliver a full-featured solution that includes intelligent control at the wellhead along with monitoring, analysis, and control at the desktop.

Our real-time software collects trends and provides analysis, so you’re always aware of temporary changes in the system.

This system can often react to changing fluid levels and return to normal operations with no need for you to intervene. By identifying trends, the system continuously monitors ESP performance and provides automated analysis and intelligent alarms in real time.

Litewell’s ESP electronics and comprehensive software provide the monitoring and analysis solutions you need to optimize production, increase operational efficiencies, and maximize profitability in ESP wells.